ఉత్పత్తి ముగిసిందిview

The Everwell CF-25AV Filter Drier is designed for use in refrigerant liquid lines. It effectively removes moisture and contaminants from the refrigerant, protecting the compressor and other system components from damage and ensuring optimal system performance. This product is suitable for various refrigeration and air conditioning systems, including chest freezers, commercial kegerators, compact fridges, compressor wine fridges, miniature kegerators, mini freezers, mini fridges, portable fridges, undercounter freezers, and upright freezers.

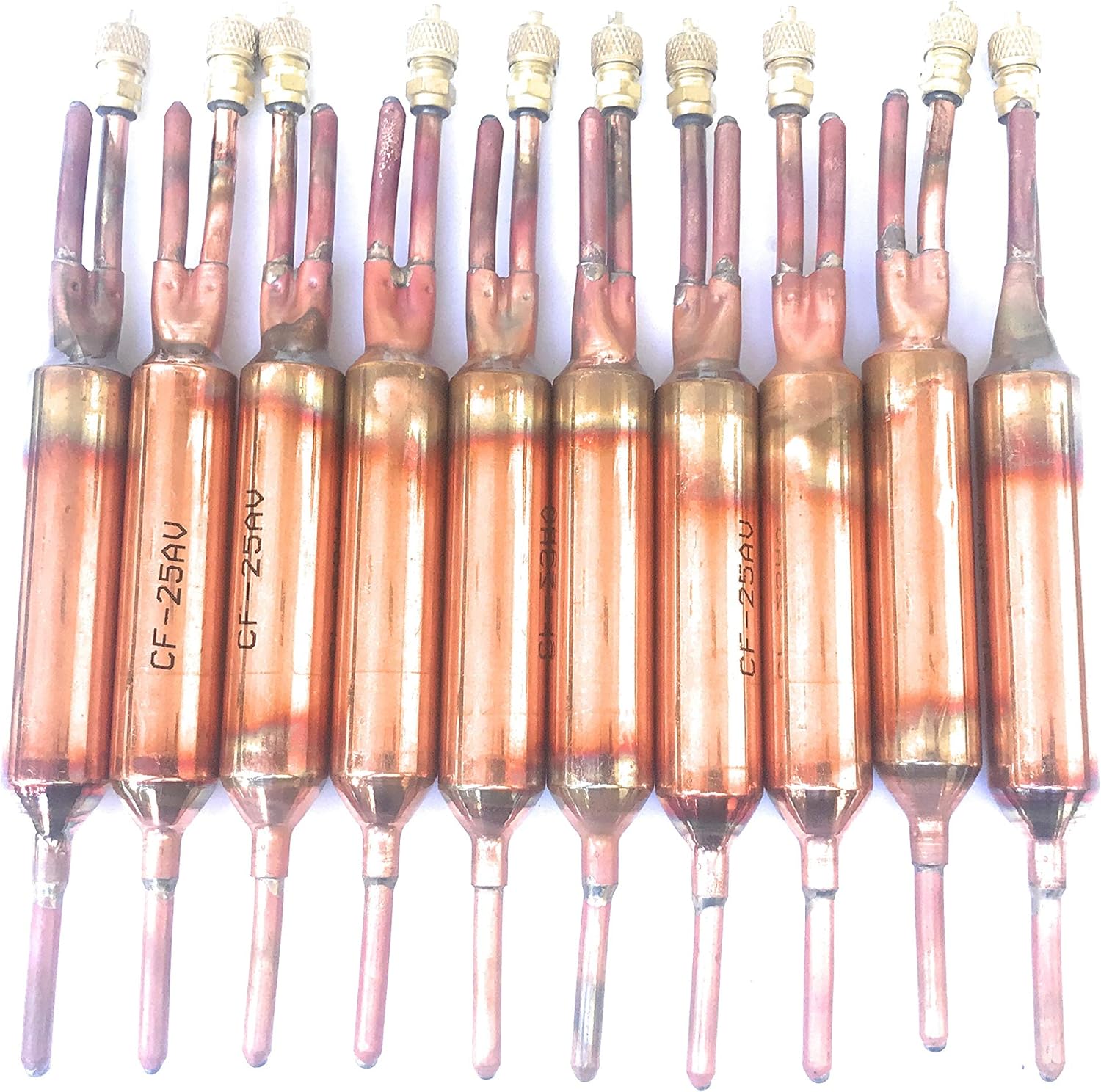

Image: A set of ten Everwell CF-25AV filter driers, showcasing their copper construction and charging valves.

భద్రతా సమాచారం

హెచ్చరిక: This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm (Proposition 65). Always handle with care and follow all local regulations regarding refrigerant handling and disposal.

- Always wear appropriate personal protective equipment (PPE), including safety glasses and gloves, when working with refrigerants and refrigeration systems.

- Ensure the system is depressurized before attempting any installation or maintenance.

- Avoid direct contact with refrigerant, as it can cause frostbite.

- Work in a well-ventilated area to prevent the accumulation of refrigerant vapors.

- Do not apply excessive force or bend the copper tubing excessively, as this can lead to damage or leaks.

సెటప్ మరియు ఇన్స్టాలేషన్

The Everwell CF-25AV filter drier is designed for easy integration into existing or new refrigeration systems. It features a 1/4" inlet and 1/4" outlet, along with a charging valve for convenience.

- వ్యవస్థ తయారీ: Ensure the refrigeration system is completely evacuated and free of pressure before beginning installation.

- Identify Flow Direction: The filter drier should be installed in the liquid line between the condenser and the metering device (e.g., expansion valve). While filter driers are typically bi-directional, it is good practice to ensure the flow aligns with any internal markings if present.

- కటింగ్ ట్యూబింగ్: Carefully cut the existing liquid line tubing to the appropriate length to accommodate the filter drier. Ensure clean, burr-free cuts.

- Brazing/Soldering: Braze or solder the filter drier into the liquid line using appropriate techniques and materials. Protect the drier body from excessive heat during brazing to prevent damage to the desiccant material inside. Use a wet rag or heat sink paste around the drier body.

- లీక్ చెక్: After installation, perform a thorough leak check using nitrogen or a suitable leak detection method to ensure all connections are secure and leak-free.

- తరలింపు మరియు ఛార్జింగ్: Evacuate the system to a deep vacuum to remove all non-condensable gases and moisture. Then, charge the system with the appropriate refrigerant according to the manufacturer's specifications. The integrated charging valve can be used for this purpose.

చిత్రం: వివరణాత్మక view of several filter driers, highlighting their construction and connection points.

Image: A single filter drier unit, clearly showing the main body, copper tubes, and the brass charging valve.

ఆపరేటింగ్ ప్రిన్సిపల్స్

The filter drier serves as a critical component in a refrigeration system's liquid line. Its primary functions are:

- తేమ తొలగింపు: The desiccant material inside the drier absorbs moisture that may be present in the refrigerant, preventing the formation of ice in the metering device and avoiding acid formation which can corrode system components.

- Contaminant Filtration: A filter screen or pad within the drier traps solid contaminants such as dirt, metal shavings, and sludge, preventing them from circulating through the system and damaging the compressor or clogging the metering device.

By performing these functions, the filter drier helps maintain the longevity and efficiency of the refrigeration system.

నిర్వహణ

Filter driers are generally considered maintenance-free components, but they have a finite capacity for moisture and contaminant absorption. They should be replaced under the following circumstances:

- After Compressor Burnout: A compressor burnout can introduce significant contaminants and acid into the system, necessitating the replacement of the filter drier.

- After System Opening: Any time the refrigeration system is opened for service (e.g., component replacement), the filter drier should be replaced to ensure any introduced moisture or contaminants are removed.

- Signs of Restriction: If there are signs of restricted refrigerant flow in the liquid line (e.g., a significant temperature drop across the drier, reduced system performance), the filter drier may be clogged and require replacement.

Regular system checks by a qualified technician can help identify when a filter drier replacement is necessary.

ట్రబుల్షూటింగ్

While filter driers are passive components, issues related to them can manifest as system problems. Here are some common troubleshooting scenarios:

- Restricted Refrigerant Flow: If the filter drier becomes saturated with moisture or clogged with debris, it can restrict refrigerant flow. Symptoms include high head pressure, low suction pressure, and a significant temperature difference across the drier (the outlet being noticeably colder than the inlet).

- Moisture-Related Issues: Inadequate moisture removal can lead to ice formation at the metering device, causing intermittent or complete blockage of refrigerant flow. This might present as fluctuating system performance or complete shutdown.

- Acid Formation: If moisture and contaminants are not removed, they can react with the refrigerant and oil to form acids, leading to corrosion of internal components. This is often a long-term issue but can be indicated by oil analysis.

If any of these issues are suspected, it is recommended to consult a qualified HVAC/R technician for diagnosis and repair, which will likely involve replacing the filter drier and potentially other system components.

స్పెసిఫికేషన్లు

| ఫీచర్ | వివరాలు |

|---|---|

| మోడల్ సంఖ్య | CF-25AV |

| ఇన్లెట్ పరిమాణం | 1/4 అంగుళం |

| అవుట్లెట్ పరిమాణం | 1/4 అంగుళం |

| Molecular Sieve (Desiccant) | 25 గ్రాములు |

| Quantity per Bag | 10 యూనిట్లు |

| వస్తువు బరువు (యూనిట్కు) | Approximately 0.22 lbs (2.2 lbs for 10 units) |

| ప్యాకేజీ కొలతలు | 12.13 x 8.62 x 1.81 inches (for 10 units) |

| తయారీదారు | Everwell |

Image: A diagram illustrating the approximate dimensions of the filter drier, including overall length and body length.

వారంటీ మరియు మద్దతు

This product is typically covered by a standard return policy. For specific warranty details, terms, and conditions, please refer to the purchase agreement or contact the seller directly. Everwell products are designed for professional use; therefore, it is recommended that installation and service be performed by qualified technicians.

For technical support or inquiries regarding product performance, please reach out to Everwell customer service through their official channels or the retailer from whom the product was purchased.